Elon Musk’s Bold Chip Plans Begin to Unfold With Advanced Packaging Plant Set for US by 2026

Elon Musk is making strides to transform the American chip industry, setting the stage for a new era in semiconductor manufacturing. Tesla’s ambitious plans are not just talk; they are already in motion, aiming to establish a robust chip supply chain right in the heart of the United States. This effort could potentially shift the dynamics of the industry and provide a crucial domestic alternative.

Texas: The Hub of Musk’s Chip Revolution

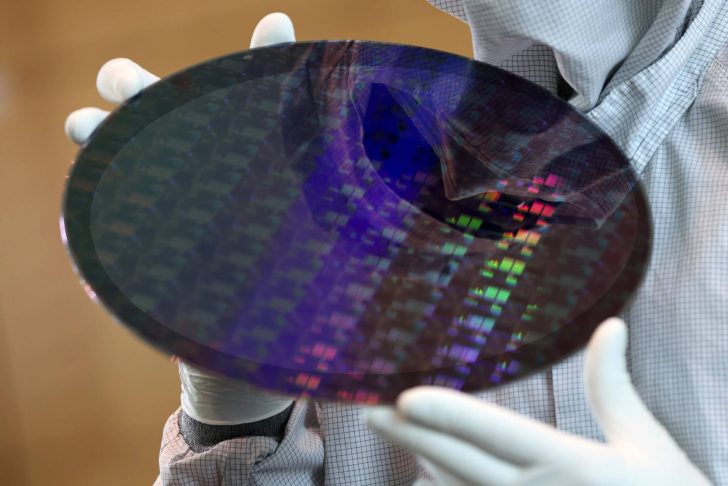

Musk has turned his attention to building up America’s semiconductor capabilities. At a recent Tesla shareholders event, he unveiled the concept of a Tesla ‘TeraFab’—a facility projected to produce 100,000 wafers monthly. Reports suggest that development is underway for a manufacturing ecosystem to support this vision. A fan-out panel-level packaging (FOPLP) plant in Texas is reportedly advancing to the equipment delivery stage, targeting volume production by the end of Q3 2026.

Elon Musk, owner of SpaceX and Tesla Inc., is making significant strides to develop a comprehensive semiconductor manufacturing supply chain in the US. Sources indicate that the fan-out panel-level packaging (FOPLP) plant in Texas has reached the equipment delivery phase and aims to commence volume production by late third quarter 2026.

– DigiTimes

The Texas facility is expected to alleviate a critical bottleneck in the US supply chain by leveraging FOPLP technology. SpaceX oversees its development, initially focusing on producing components for Starlink, like RF front-end chips. This advanced technology allows for the integration of RF chips and power ICs into a single module, making it essential for Starlink’s operations.

Project ‘TeraFab’ and the Future of US Chip Supply

Equipment installation at the Texas facility has reportedly begun, with limited production slated for Q3 2026. Initial output is expected to reach 2,000 units per month. Along with this FOPLP facility, Tesla already operates a PCB factory in Texas, underscoring a serious commitment to building an independent chip supply chain. This initiative indicates that the Project ‘TeraFab’ could indeed become a long-term fixture in the tech landscape.

Musk’s drive to establish chip fabs in the US goes beyond competing with giants like TSMC. The aim is to ensure a stable supply chain, providing a strategic alternative in the event of geopolitical issues in Taiwan. Furthermore, Tesla’s collaboration with Intel on advanced packaging points towards the potential for a more formal partnership in the future.