Intel’s Innovative Heat Spreader Solution

Intel researchers have unveiled a groundbreaking approach to enhance chip cooling efficiency, focusing on simplifying heat spreader assembly. This advancement promises cost-effective and superior designs for the company’s “extra-large” advanced packaging chips. By adopting a novel method, Intel aims to overcome the limitations of traditional heat spreaders, facilitating the production of larger, more complex chip packages.

Revolutionizing Heat Spreader Design

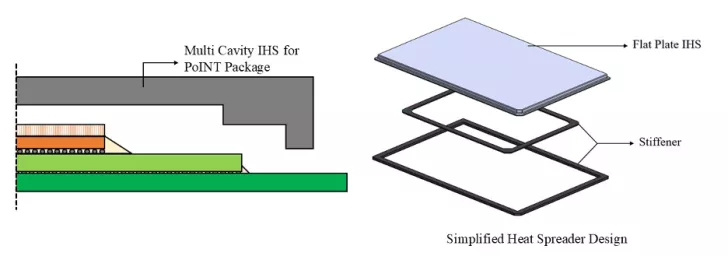

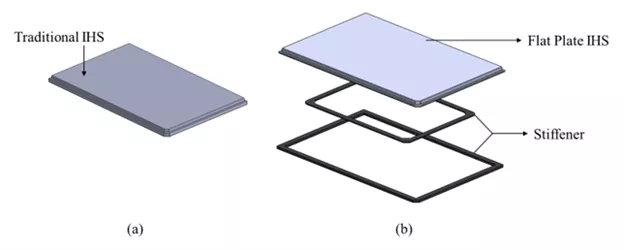

In a recently published research paper titled “A Novel Disaggregated Approach of Assembling Integrated Heat Spreader for Advanced Packages,” Intel Foundry researchers detailed a disaggregated approach to heat spreaders. This new design not only improves manufacturing ease and value but also enhances cooling for high-power chips. The innovative assembly method can reduce package warping by up to 30% and decrease thermal interface material voids by 25%, significantly improving thermal management for advanced packages.

Enhanced Manufacturing and Performance

This new heat spreader solution is tailored for Intel’s “Advanced Packaging” solutions, which involve chips with multiple stacking layers and chiplets. By breaking down complex heat spreaders into simpler components, the process leverages existing manufacturing processes, using optimized adhesives and improved stiffeners for higher thermal interface performance. This new method allows Intel to develop extra-large chips, which were previously unfeasible with traditional techniques.

Future Implications and Developments

Traditional chip designs, often limited by the complexity and size of heat spreaders, face higher costs and delays due to intricate manufacturing requirements. Intel’s research advocates for the separation of these components, allowing for more flexible production through conventional methods. This approach not only achieves a 7% improvement in package coplanarity but also opens the door for future adaptations in cooling solutions, including high-conductivity metal composites and liquid cooling integrations.