The race in the semiconductor industry is heating up as TSMC aims to push forward its production capabilities in the United States. The company’s ambitious plan for its Arizona facility is set to revolutionize the chip market, with reports suggesting that 3nm mass production could begin as early as 2027, a year ahead of the initial schedule. This move reflects TSMC’s response to increasing competition and the growing demand for advanced semiconductor nodes.

TSMC’s Bold Strategy for U.S. Expansion

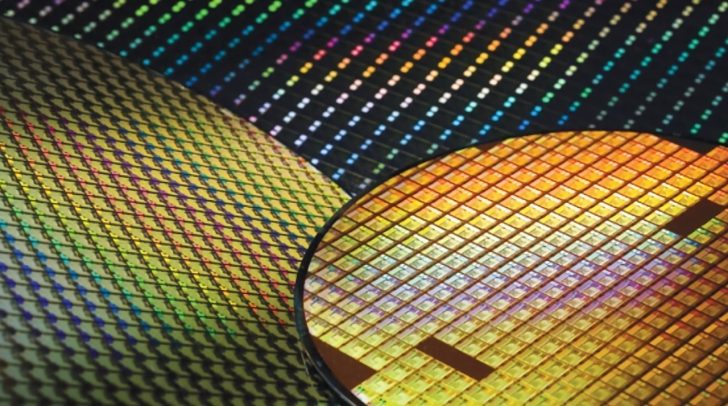

The Arizona plant represents a monumental investment for TSMC, as it becomes a focal point in shifting production to align with the “Made in USA” initiative. By committing up to $300 billion, TSMC seeks to build a sturdy supply chain across the nation. Reports suggest that TSMC is accelerating its plans, with 3nm technology arriving sooner than expected to meet the high market demand for cutting-edge nodes.

Currently, TSMC’s first Arizona facility is producing 4nm chips, while the second plant is gearing up for 3nm mass production targeted for 2027. The increasing need for high-performance computing and AI applications is driving this rapid development. Reports indicate that 3nm technology could be operational in the Arizona fab nearly a year earlier than planned, highlighting TSMC’s aggressive strategy in the U.S. market.

Facing Fierce Competition

The competitive landscape is evolving rapidly, with Intel’s advancements in the 18A process and Samsung’s strategic focus on 2nm wafer production. Samsung’s recent deal with Tesla exemplifies the shift toward alternative suppliers to TSMC. In light of these developments, TSMC is compelled to enhance its production capabilities to maintain its market position.

Despite challenges such as rising capital expenditures and labor shortages, TSMC is determined to expand its fab network, including new projects in Japan. The company recognizes that meeting the surging demand requires substantial capacity growth.