In a groundbreaking move, the Taiwanese chip manufacturer TSMC is making waves with its latest and most sophisticated facility, set to usher in the era of the Angstrom-scale A14 (1.4nm) process. This ambitious undertaking marks a significant leap for TSMC as it propels forward on the technological front.

TSMC’s Monumental Investment in Cutting-Edge Technology

TSMC continues to push the boundaries of innovation, even as the company advances within the 3nm node framework. Reports suggest that TSMC has embarked on constructing the 1.4nm facility in Taichung, central Taiwan. The project is projected to cost an astounding $48.5 billion, with production anticipated to kick off by 2028.

Originally conceived as a 2nm facility, TSMC updated its plans to elevate production to the Angstrom-era level. This strategic shift aims to bolster 2nm production lines in the United States, driven by high demand from HPC and mobile clients. TSMC strives to keep pioneering technology production on home soil while scaling up older node capacities abroad to satisfy customer needs.

The Future of TSMC’s A14 Node

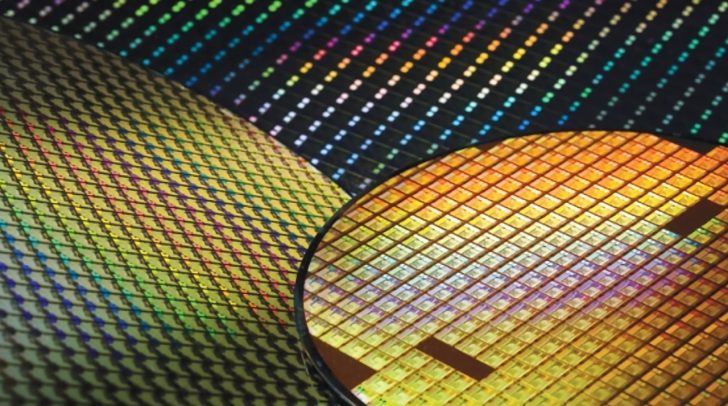

The 1.4nm facility will comprise four fabs, with the first anticipated to be operational by 2027’s end, boasting an initial mass production of 50,000 wafers. Notably, TSMC has opted not to employ High-NA EUV lithography for the A14 node, contrary to competitors like Intel who plan to use this technique for their 14A node. Instead, TSMC will focus on intricate multi-patterning methods.

The A14 node is set to attract significant interest from major players like Apple, Qualcomm, and MediaTek, along with HPC clients such as NVIDIA and AMD, who are eager to harness the node for their upcoming AI architectures.